Welding Machine Operating Procedure ~ ENDING OPERATIONS AND CLEANING UP. The area is dry and protected from combustibles. Ensure that other workers in this locality are protected from any UV IR radiation flash. SAFE OPERATING PROCEDURE ELECTRIC WELDER DO NOT use this equipment unless you have been instructed in its safe use and operation and given prior permission. Never weld in the rain or while standing in water or on wet floors. All it takes on your part is 5-10 minutes before you turn on your welder. Check to ensure the band saw blade is sharpened. Welding cutting and heating operations should conform to applicable Federal State County or City regulations for installation operation ventilation fire prevention and protection of personnel. Switch off the machine and fume extraction unit when work is completed. Regularly inspect the welding torch assembly for damage. Indeed recently is being sought by consumers around us, perhaps one of you personally. People are now accustomed to using the internet in gadgets to see image and video data for inspiration, and according to the name of the article I will talk about about Welding Machine Operating Procedure. INSPECTION AND MAITNENANCE OF EQUIPMENT AND WORK Before starting any arc welding operation you should make a complete inspection of your equipment. An operator can be subjected to many safety hazards associated with the industry. If using a clamp stand arrange as desired in the work space of the Micro-Welder Open the main supply and set to between 3 to 5 liters per minute. Motor-generator set or dieselpetrol engine-generator set or a transformer-rectifier welding set. Provides instructions on the use of the equipment both prior to and during operation. Ensures workers recognise and manage associated hazards and risks involved. Remove electrode stub from holder and switch off power source. Welding machine consists of an AC. When holding work be aware of the heat created during welding process. Always close the UV curtain to the welding bay or erecting a UV screen.

At least 20 feet away form combustible materials. All it takes on your part is 5-10 minutes before you turn on your welder. ENDING OPERATIONS AND CLEANING UP.

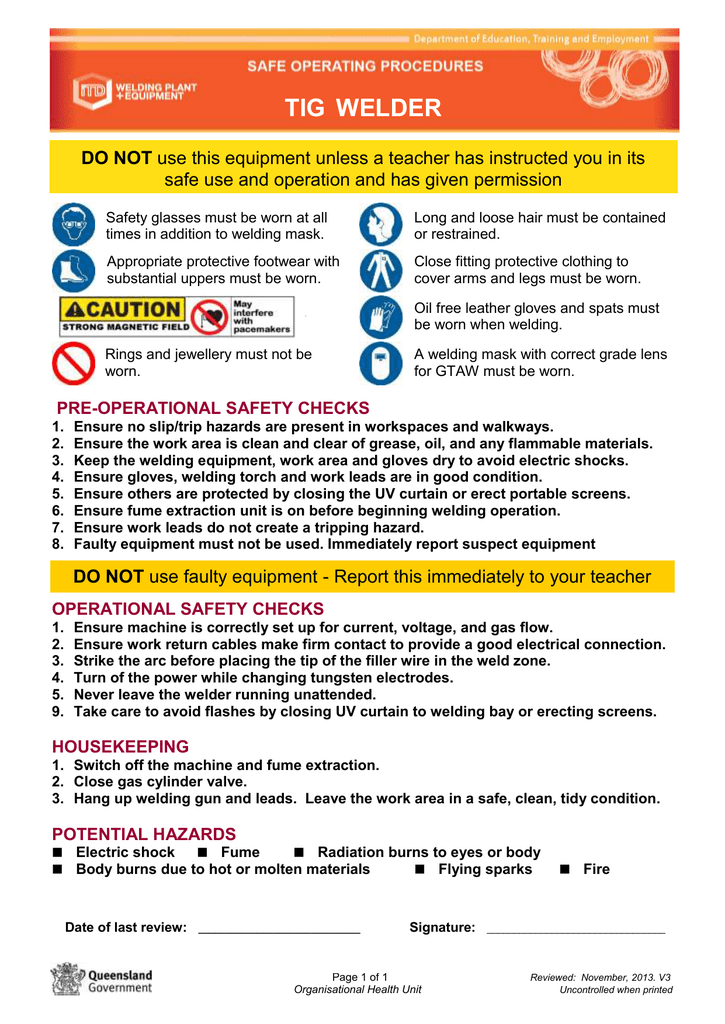

Date of last review Name Signature PERSONAL PROTECTIVE EQUIPMENT PRE-OPERATIONAL SAFETY CHECKS Read Operators Manual and Risk assessment.

When welding is finished or interrupted turn off the shielding gas at the regulator turn off the machine and secure the handpiece safely. Set the band saw at the appropriate speed for the type of stock being machined. Switch off the machine and fume extraction unit when work is completed. Ensure the electrode holder has no electrode in it before turning on the welding machine.